Global Bugs Asia plans to scale up the EntoPowder production with the new EntoFarm project starting 2023

EntoFarm methodology

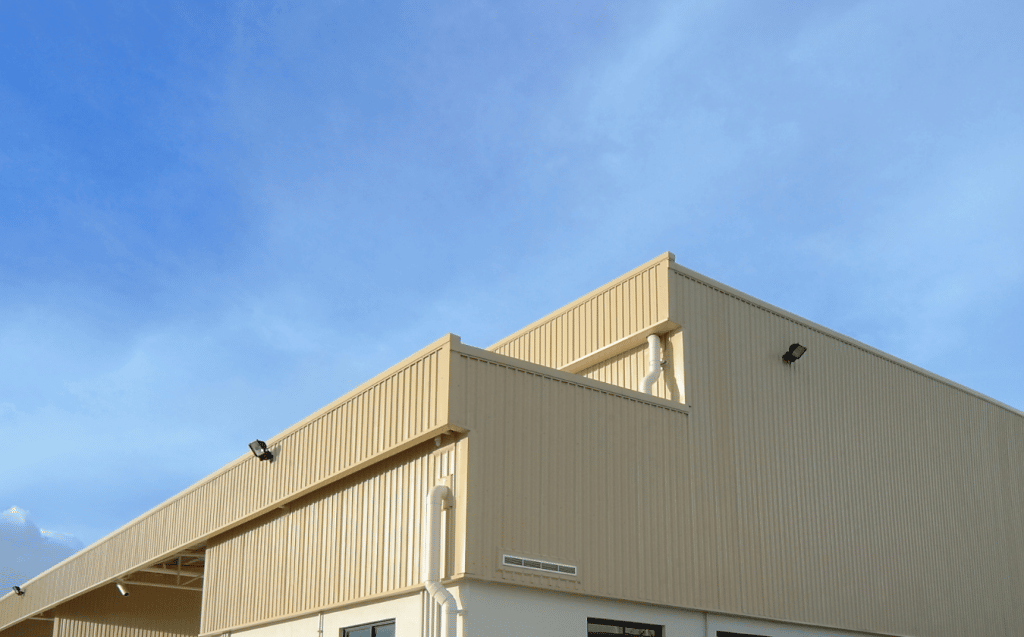

Thanks to our innovative production unit, at Global Bugs we have designed a holistic approach, from the rearing to the processing of crickets (EntoPowder production), following what we call the EntoFarm methodology. Each farm will be semi-automated, with approximately 12,000 EntoBoxes using vertical farming in 9 levels in the first-in-first-out pattern of all boxes using breeding cycles of 30 days, reaching more than 45 tonnes of cricket powder per year and EntoFarm.

The production and process areas will be constructed in line with the demands from European Food Safety Authority (EFSA) when it comes to crickets for human consumption.

As a member of the Belgium Insect Industry Federation (BiiF), we have actively been a part of the development of the dossier sent to EFSA for the approval of the house cricket as food for human consumption in the European Union.

Complying to EFSA standard means that we will also fulfil global demands for the export of crickets, entopowder and CPG products.

The implementation of vertical farming principles and semi-automation technology allows us to scale up EntoPowder (cricket powder) production and reduce production costs, resulting in the delivery of widely and affordable cricket proteins. Besides, the EntoFarm is designed to be self-sustainable by using rainwater, sunlight, reusable airflow, local raw materials, and small amounts of energy, to help limit global warming to 1.5° C by 2050.